Some Known Factual Statements About Sheroz Earthworks

Table of ContentsOur Sheroz Earthworks DiariesSheroz Earthworks Things To Know Before You Get ThisThe 8-Minute Rule for Sheroz EarthworksFacts About Sheroz Earthworks RevealedAll about Sheroz Earthworks

Below we offer a review of device control and automation and rundown five reasons why hefty construction can benefit from reality capture, whether you are a driver, a designer, or a task proprietor. We normally divided maker control right into 2 groups.

The 3D design normally comes in the type of triangulated surface area versions or digital terrain designs (DTM), which are posted using a USB stick in the case of a single device, or even more conveniently for numerous machines, using, a cloud-based platform for sharing information that can be managed centrally.

Sheroz Earthworks Things To Know Before You Buy

Machine automation does the very same estimations for the setting yet has an included interface that takes some of the job out of the driver's hands. By utilizing hydraulics or linking to systems on the machine, device automation can place the equipment itself and meet the preferred worth, such as excavating to the proper deepness.

The trend in the market is for assistance systems to end up being increasingly more automated. The excavator system specifically has actually seen lots of developments over the past year, consisting of the semi-automatic excavator. https://linktr.ee/floydoverbeck4500. We have piercing systems that can stop piercing instantly when the equipment control informs the system that it's struck the preferred depth, and solutions for dozers and interface with the machines' hydraulic system for an automated operation

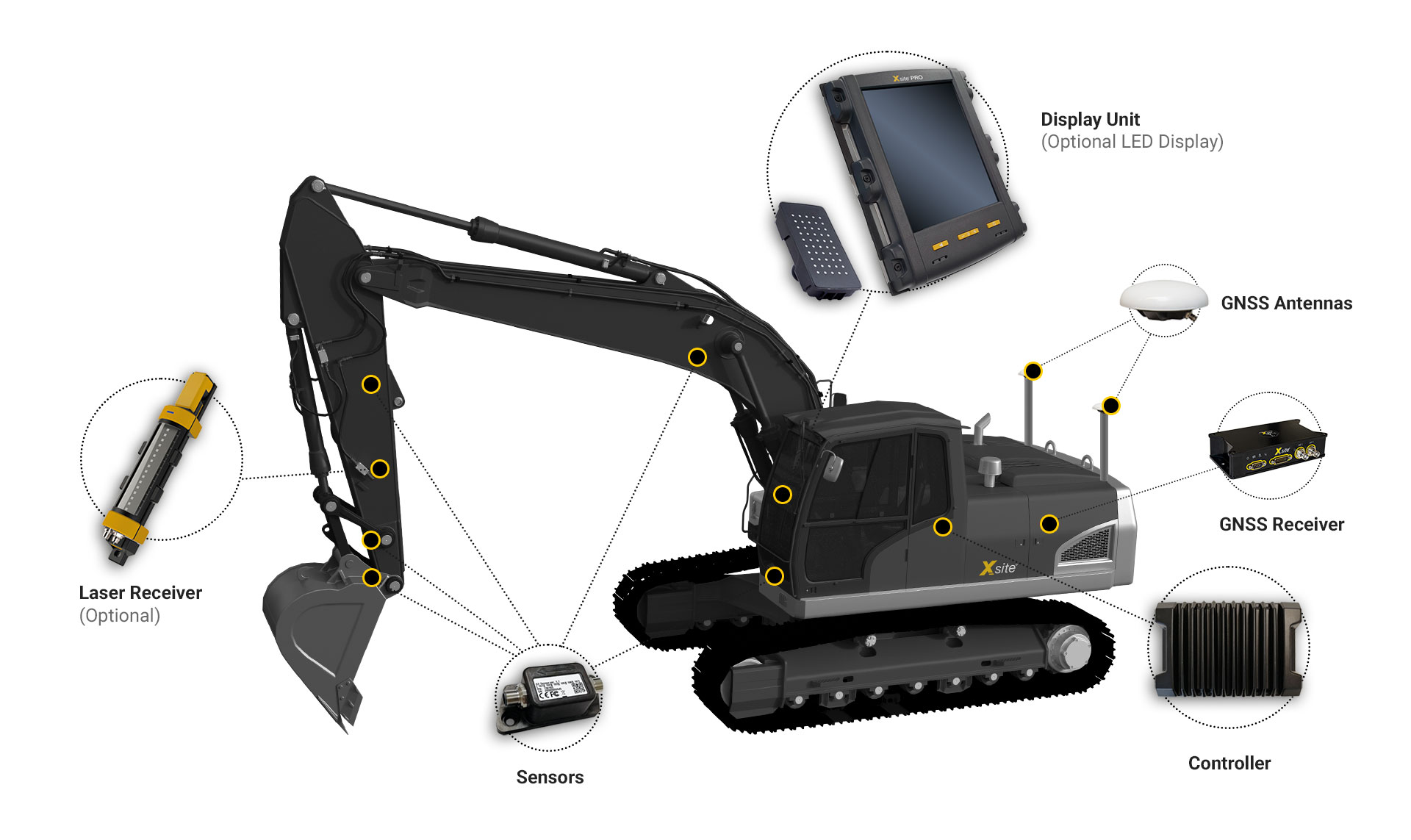

Typically, maker control needs some instruments to position itself, and there are a couple of ways of doing this. In easy cases, if you're just concerned with height, for instance, you can utilize a rotating laser. We refer to this as a 2D device control system. You can make use of an overall terminal tor laser scanner to acquire placement and height, which is true 3D machine control.

The most usual positioning kind for machine control is GNSS, which will certainly position the device to 3D accuracy of about 30mm. In all these situations, the first positioning is not done to the setting of the tool itself, so there are other sensors mounted to transfer the placement where the sensor remains on the back of the equipment to the get in touch with point of the tool.

Facts About Sheroz Earthworks Revealed

They can examine the precision of their very own work and quickly imagine the finished product by checking out the design on the screen. All this extra details permits them to obtain the work right first go, lowering any rework. For the engineer, equipment control suggests that there are no fixes or batteries to knock in for hours at a time as the details is all there in the equipment.

The time that they require to spend near hefty equipment a typical place for accidents is decreased. Machine control means that there's much less material waste as drivers can be much more accurate in their job. This also means much less fuel is eaten, both variables in assisting building and construction firms fulfill the task's environmental targets.

It's easy to set your evasion zone and a trigger range where the equipment control system will notify the operator to threat. As soon as the equipment goes within the trigger distance, the system sends out a warning with an audible alarm, and the display goes red. topcon. It's feasible to obtain data back from the machine control system in the type of measured points for the as-built coverage

Leica Geosystems' solution for heavy building and construction applications provides a unified hardware platform with an usual software application interface throughout our maker control portfolio., while Leica ConX, the cloud-based and straightforward performance system for boosted project efficiency, rounds off Leica Geosystems' goal to accomplish a digitised building and construction website.

What Does Sheroz Earthworks Do?

It is obvious that there is a lack of fresh ability entering the industry. In certain, professionals have difficulty bring in youngsters and, because of this, there are fewer operators entering the occupation (topcon). Needs to this pattern continue, the market will be left with a shortage of skilled and reputable drivers, which means that the quality and efficiency of projects will be influenced by a significant skills space

What Does Sheroz Earthworks Do?

When taking a look at the present building landscape, it is clear that, despite its considerable benefits, equipment control automation is not being taken on across all makers at an equivalent rate (https://lwccareers.lindsey.edu/profiles/5240299-floyd-overbeck). As a matter of fact, although automation is being welcomed on equipments like graders and dozers, the uptake has been much slower for excavators, with the adoption price of automated machine control on these devices still estimated at around 10% in Europe in contrast to a price of over 50% for dozers.